28 Critical PSV Evaluations and Expert Design for Enhanced Safety

REDD aided a refinery in analyzing a series of PSVs to determine the necessary modifications needed to bring the system up to the refinery’s standards.

Investigating PSVs for a More Efficient System

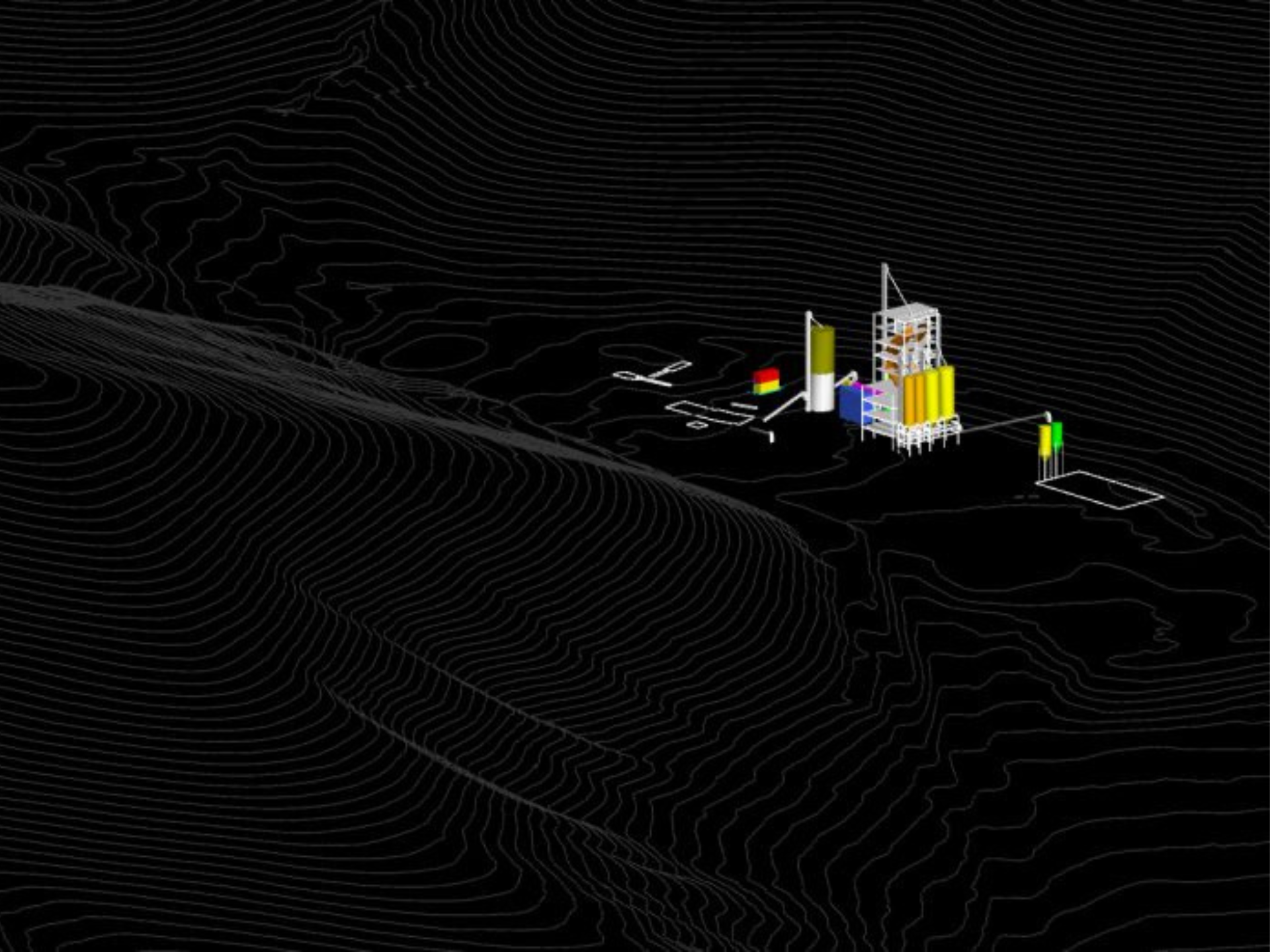

REDD supported a local refinery with engineering to advance from a feasibility project to a design stage. The project involved investigating 28 different PSVs, and determining whether the piping or the PSV needed to be resized to bring the inlet and outlet pressure differences within the required percentages, as per API 520 and ASME I and VIII.

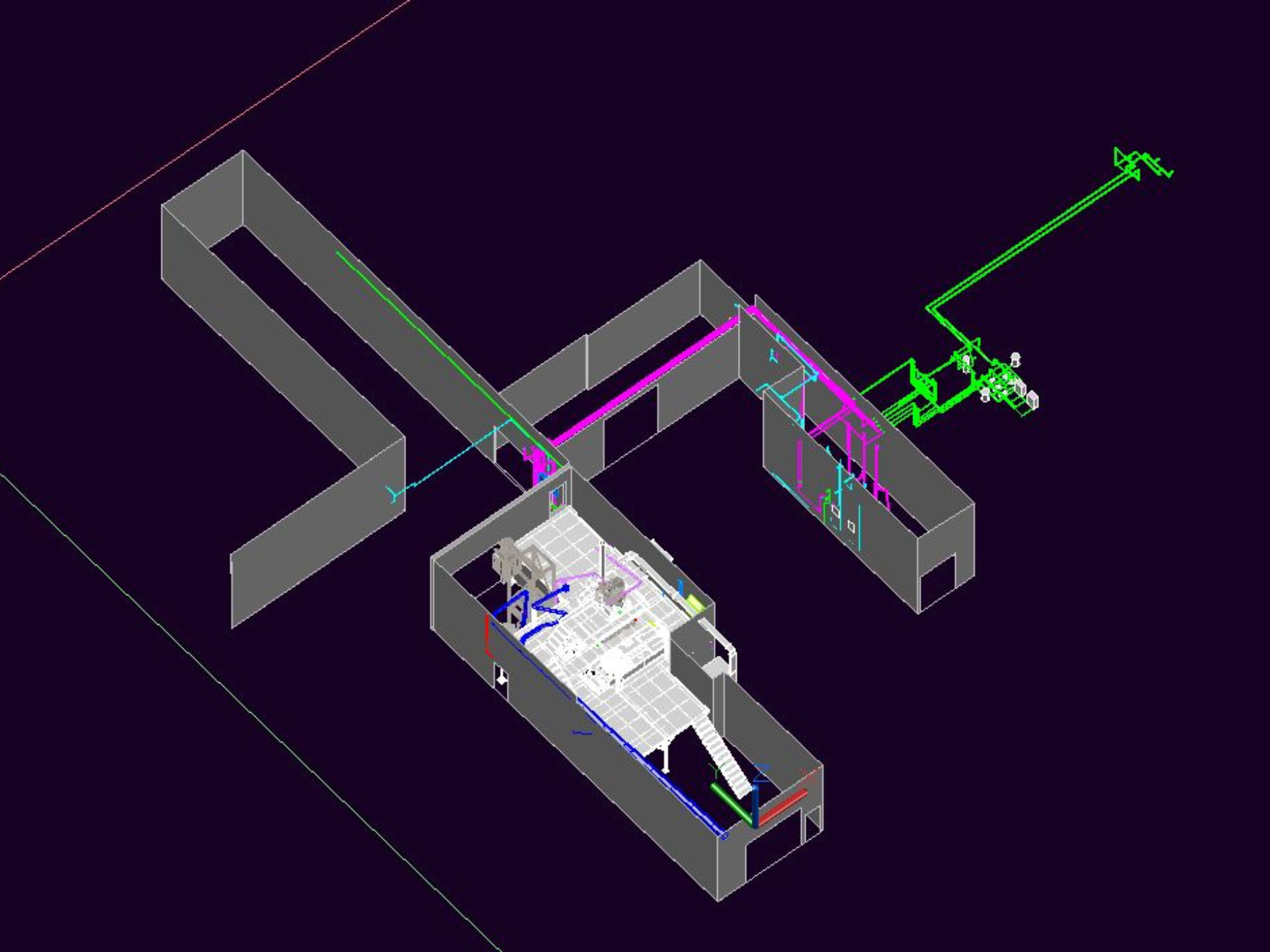

After field investigating the redlined P&IDs received from the client, REDD worked with the client to identify each PSV and their respective proposed routing, as well as any documentation necessary to begin building the 3D models. Once this was accomplished, production of the 3D models began. Each PSV was modeled individually along with some new structural platforms, which allowed construction drawings to be created more efficiently.

After finalizing the models and receiving final approval from the client, REDD developed data sheets for the new PSVs and related instrumentation, as well as IFA, IFR, and IFC drawing packages.

The clients aggressive schedule required many total manhours. Despite this, REDD was able to provide a complete package within the deadline that exceeded the client’s expectations.