500 Barrel Slug Catcher EPC

The Value of Client Satisfaction

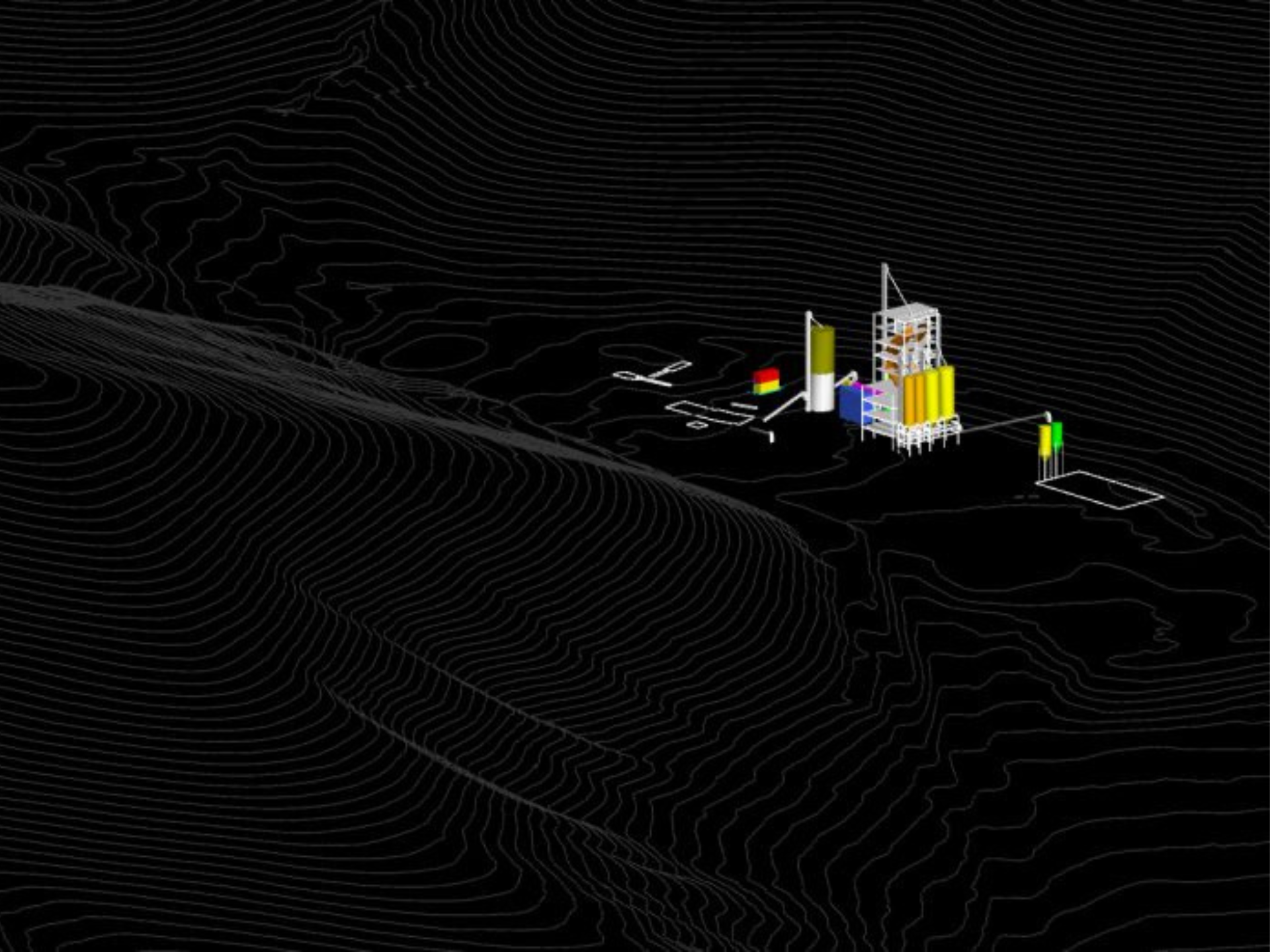

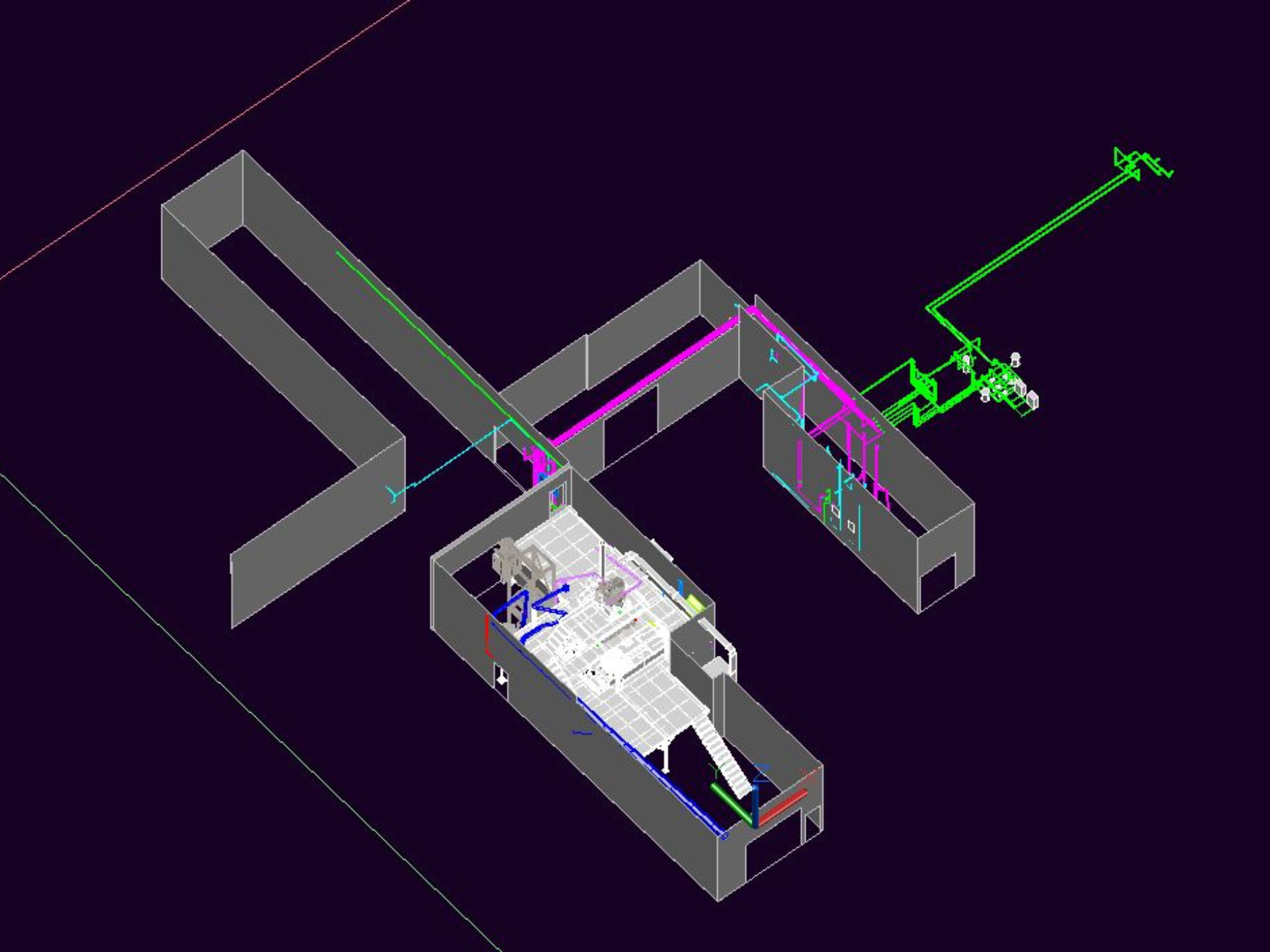

REDD provided full EPC services—engineering, procurement, and construction—for a gas plant in Church Buttes, Wyoming, which required a larger slug catcher to handle the large slugs exiting the pipeline. To rectify this issue, the client requested that REDD provide the design, construction management, and all associated piping required for a 500-barrel slug catcher.

REDD oversaw all aspects of the installation, including earthwork excavation for the slug catcher foundation and pipe support piers using hydro-vac, concrete work, coordination with the slug catcher fabricator, engineering and design of all associated piping and equipment, and complete construction management. Our team was consistently onsite to resolve any unforeseen issues and supervised the proper installation and hydrostatic testing of all piping and the slug catcher.

With a strong focus on scope, schedule, and budget, REDD earned the client’s trust—resulting in a glowing recommendation and INVITED US BACK TO INSTALL ANOTHER SLUG CATCHER FOR THEIR CANYON CREEK PLANT.