Next-Gen Ammonium Nitrate Offloading System Powers Efficient 25-Minute Rail Unloads

Engineering an Optimized Ammonium Nitrate Offloading System with Advanced Rail Stations and Storage Solutions

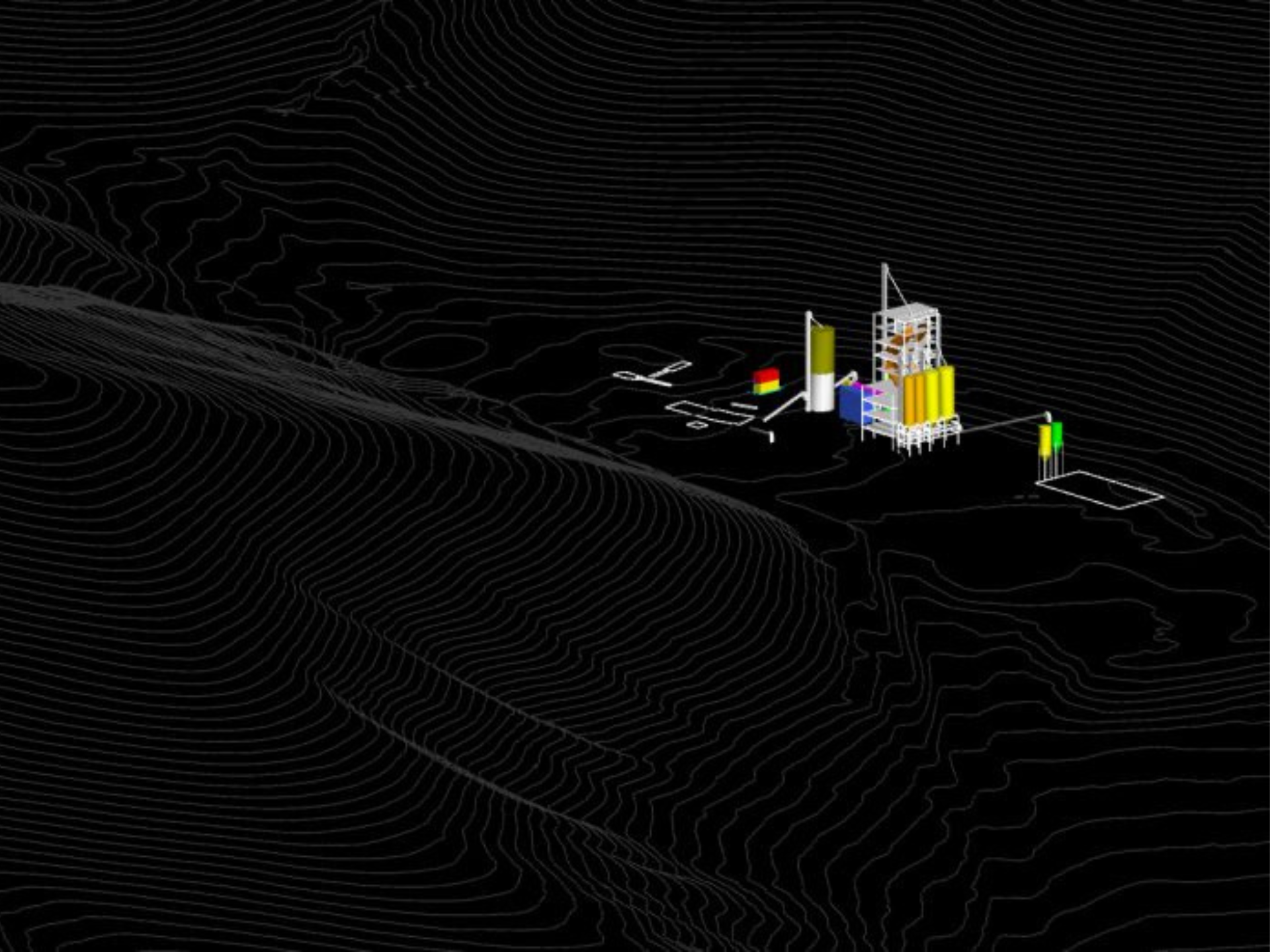

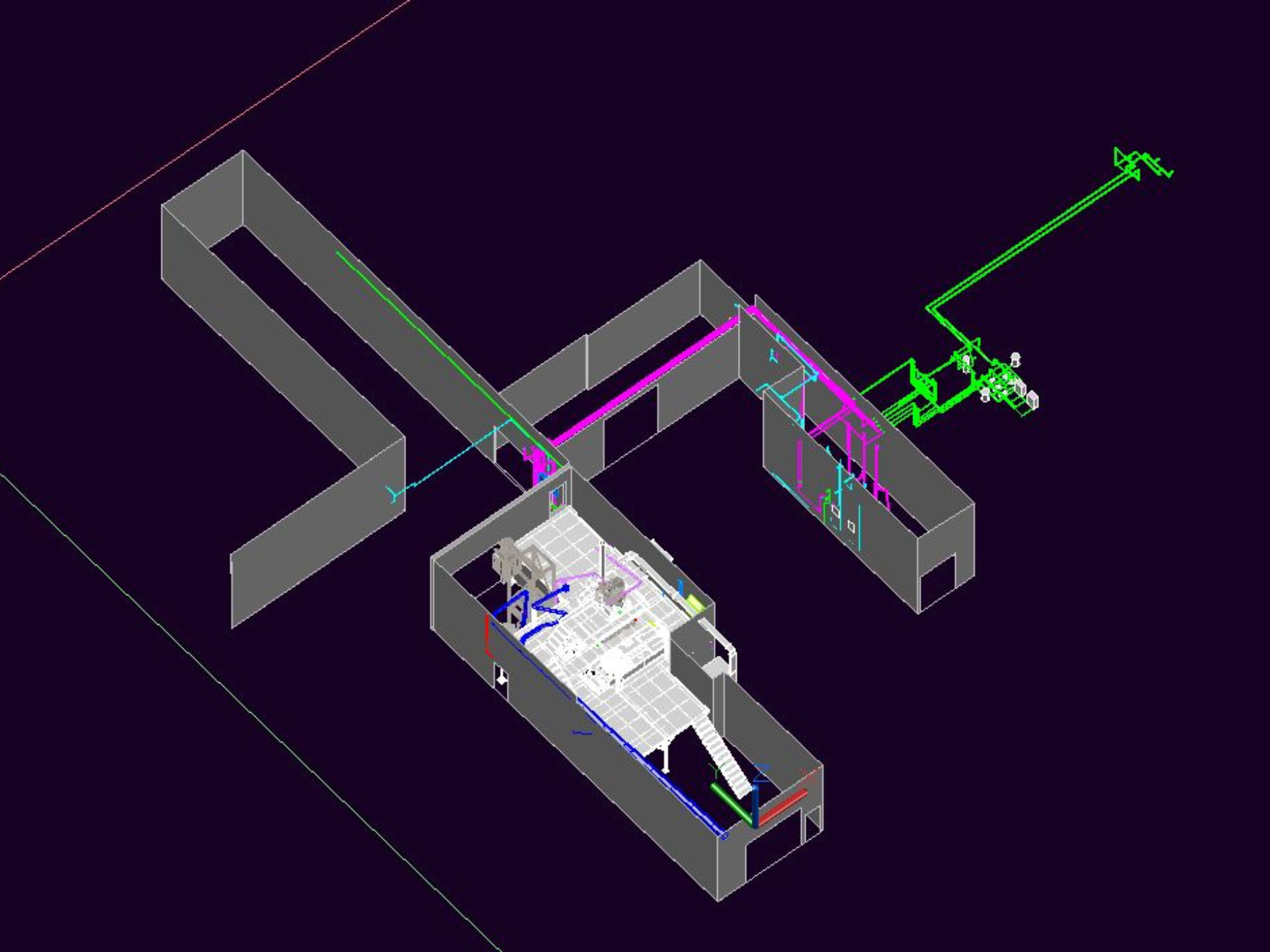

REDD provided on-site and engineering support for a recently completed project in the Southwest area, delivering a modern ammonium nitrate offloading system designed for improved efficiency and reliability. This system involved the installation of several new rail stations for offloading ammonium nitrate solution (ANS) and the replacement of an aging main ANS storage tank with a new 43-ft-diameter tank offering improved containment and safety.

The new offloading stations use compressed air to empty a railcar containing 100 tons of ANS in just 25 minutes. The ANS is transferred directly from the railcars into the new storage tank, eliminating the need for transfer pumps and significantly reducing operational costs.

With this advanced ammonium nitrate offloading system in place, the plant is now better positioned to maintain consistent operations, avoid supply chain disruptions, and meet all relevant regulatory compliance standards.