Blowdown Valve Redesign & Accessibility Improvement

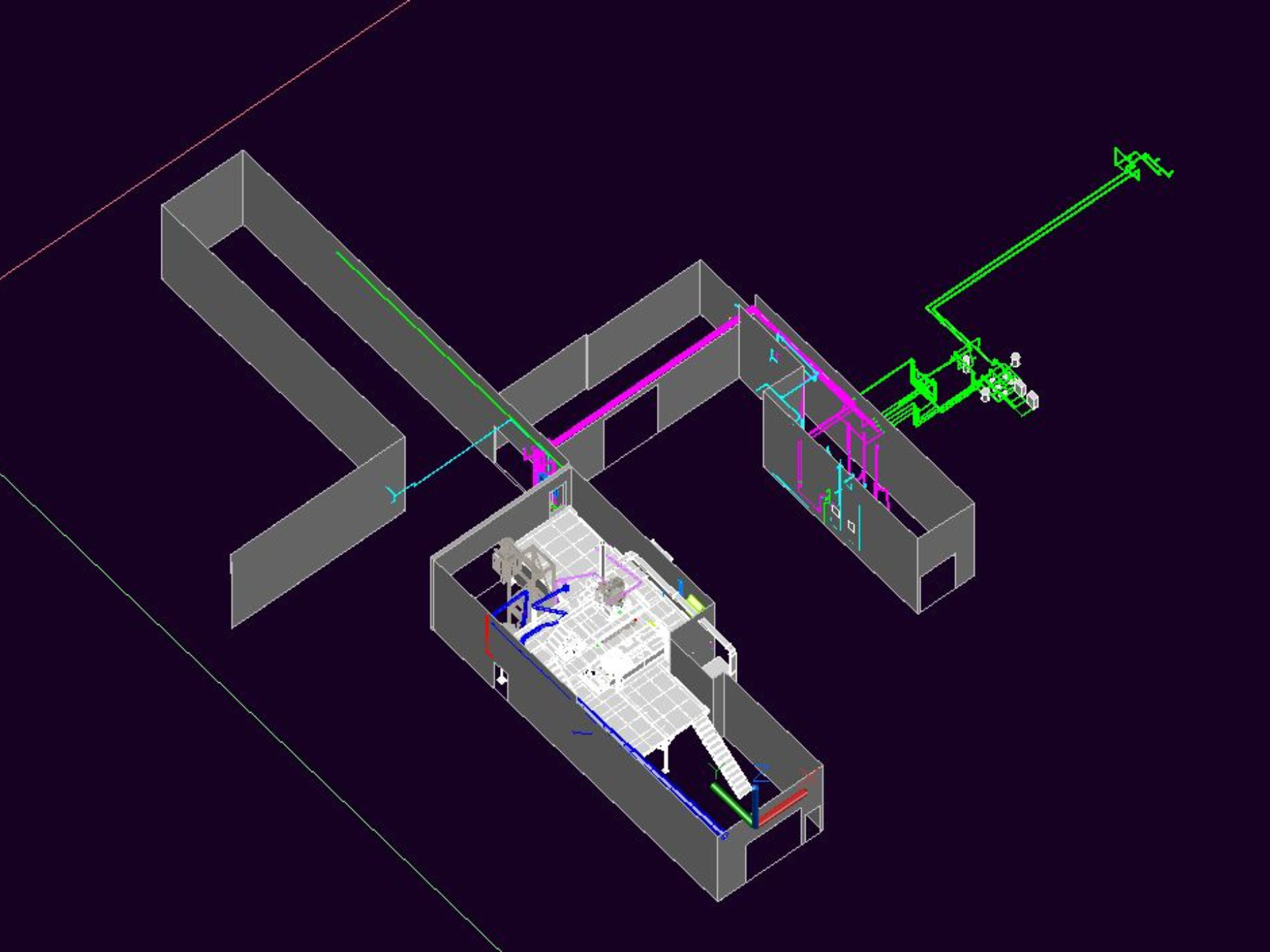

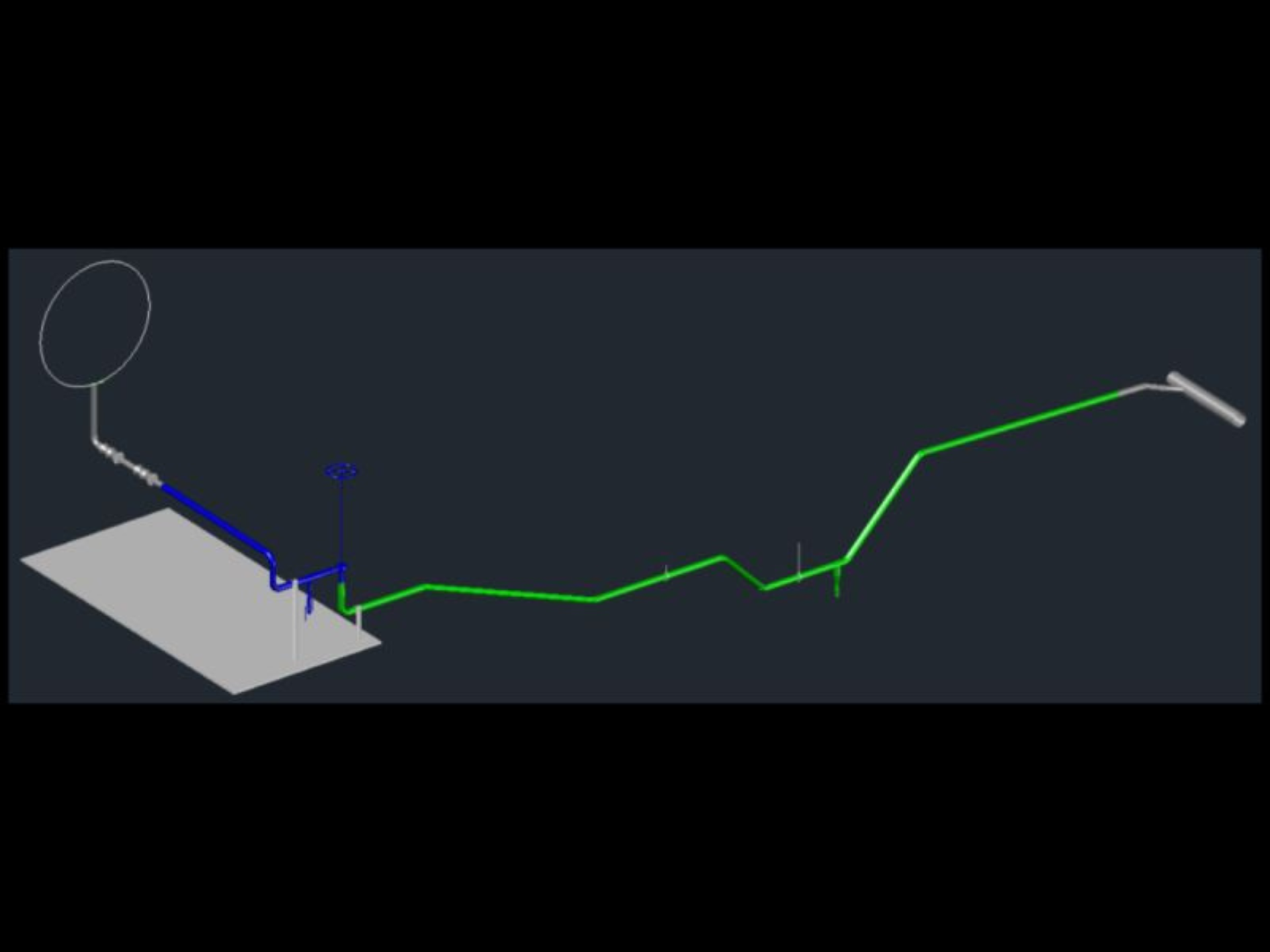

REDD supported a power plant in the Mountain West region with the redesign and improved accessibility of a blowdown valve (BDV) at their facility. The existing valve was located on a platform with limited operator accessibility, and the replacement valve did not fit the current configuration. To address this, our team engineered a rerouted pipeline design to allow for better operational access to the new valve.

Our scope of work included a 3D scan of the area to capture existing conditions. Using this data, we created a detailed 3D model of the new design and conducted model reviews with the plant’s team to ensure alignment with their operational requirements. Additionally, we performed a CAESAR II pipe stress analysis and provided a comprehensive report, along with a review of boiler codes and piping specifications to ensure compliance.

The final deliverables included an Issued for Construction (IFC) package with detailed piping plans, sections, isometric drawings with BOMs, and demolition drawings, providing the plant with the tools needed for a successful implementation.