Clarifier Feed Piping Replacement

Thinking Outside the Box, Not Just Following Orders

After many years of patching the existing piping, the client decided that it was time to explore options for a clarifier feed piping replacement during the next shutdown. To meet schedule challenges the pipe needed to be fabricated and lined prior to shutdown.

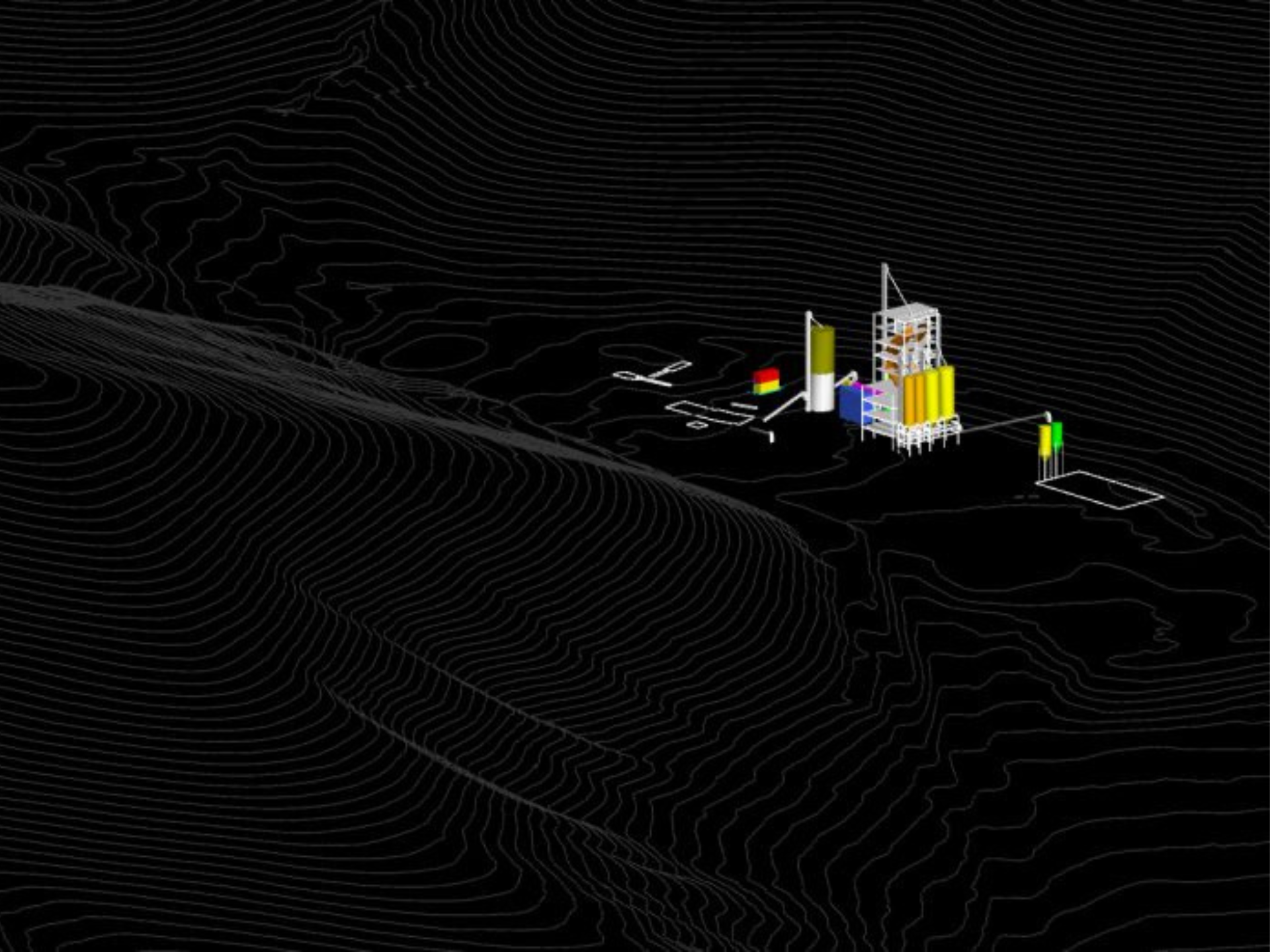

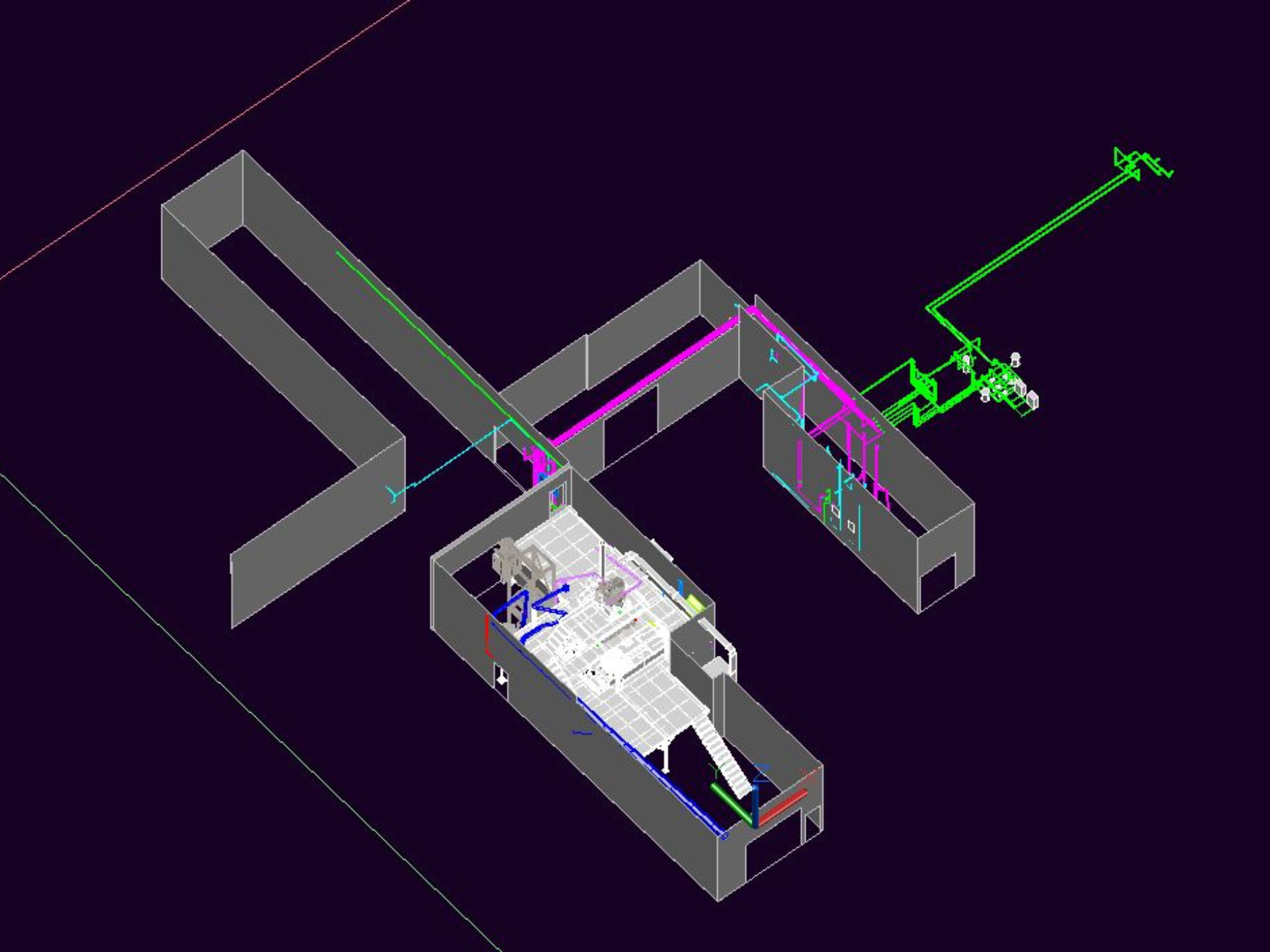

The client hired REDD to perform this difficult task. REDD personnel visited the site and, with the Client Liaison, gathered the available drawings and specifications and reviewed the pipe in the field. The pipe had a concrete to steel transition on the upstream end and a round to square transition on the downstream one.

It became quickly apparent that the connections on both ends of the pipe between transitions and pipe were different than 90 degrees, were eccentric and, due to location, would not be easily scanned or modeled with enough accuracy to ensure proper fabrication. It was apparent that if this pipe didn’t fit up properly it would extend the shutdown and potentially cost the client millions in downtime.

After exploring options with a few trusted fabricators, REDD determined an approach that solved the immediate problems with the pipe and extended its useful life.