Transforming Transmix

Custom Bult Transmix Distillation Unit

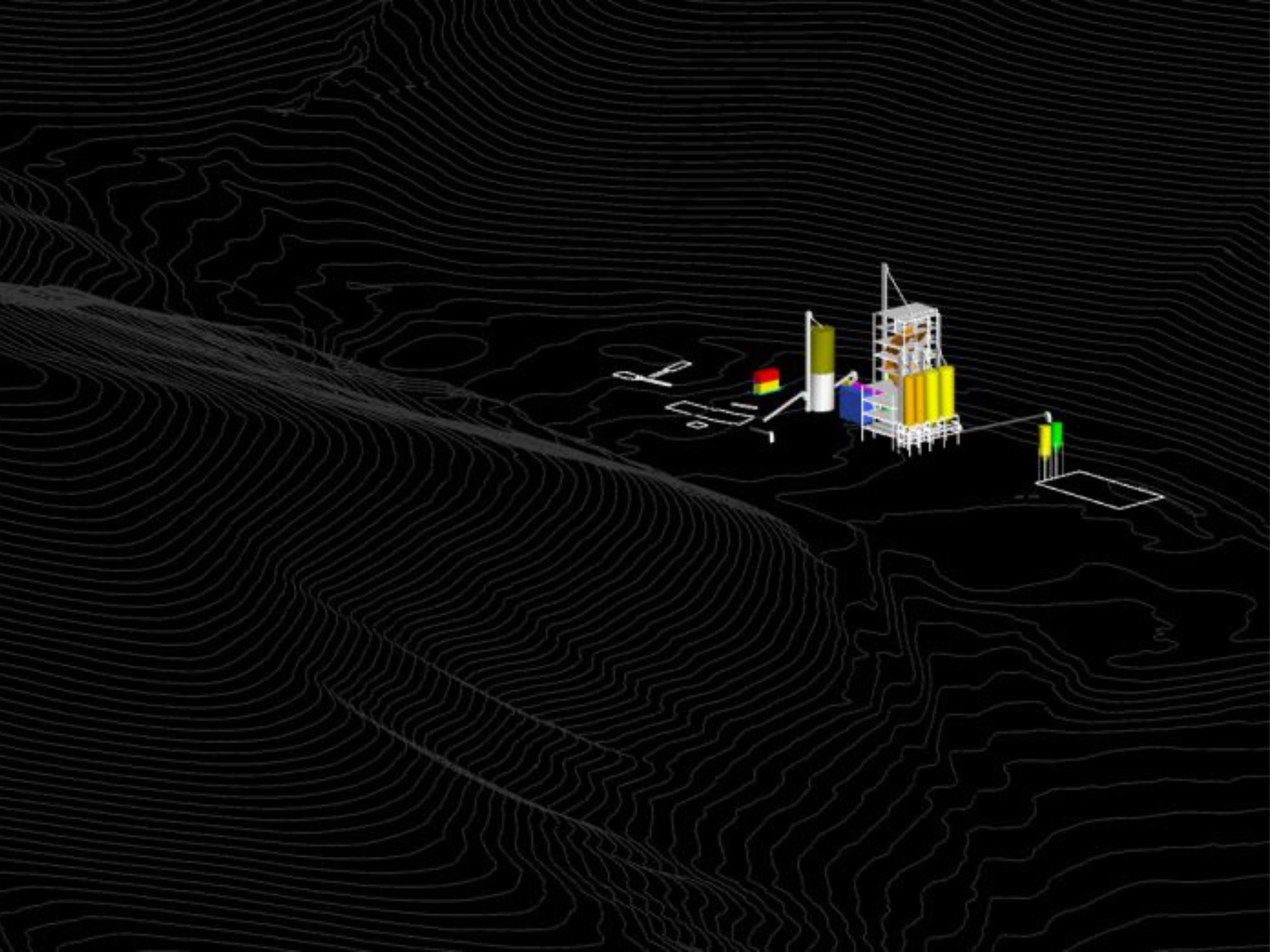

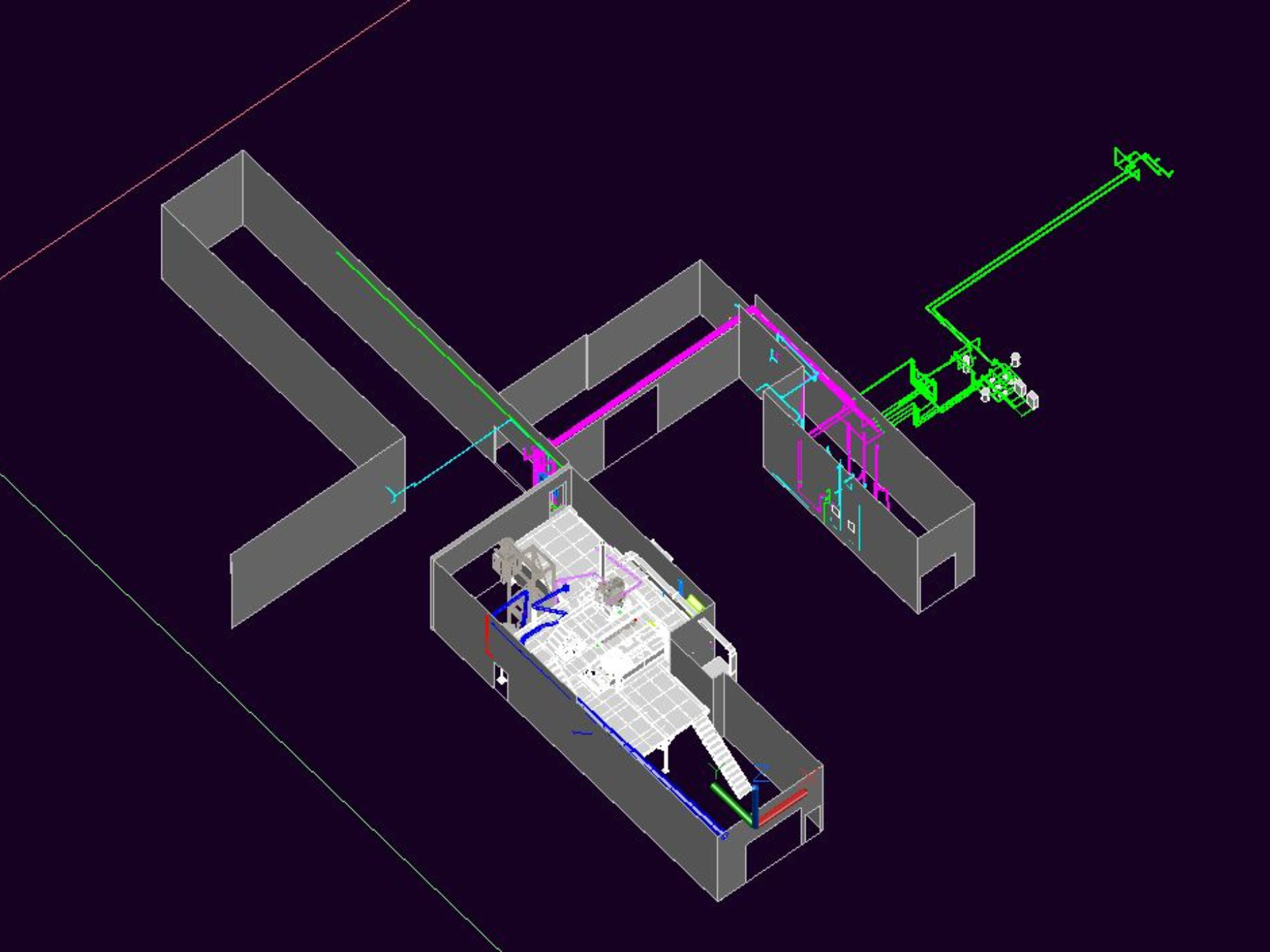

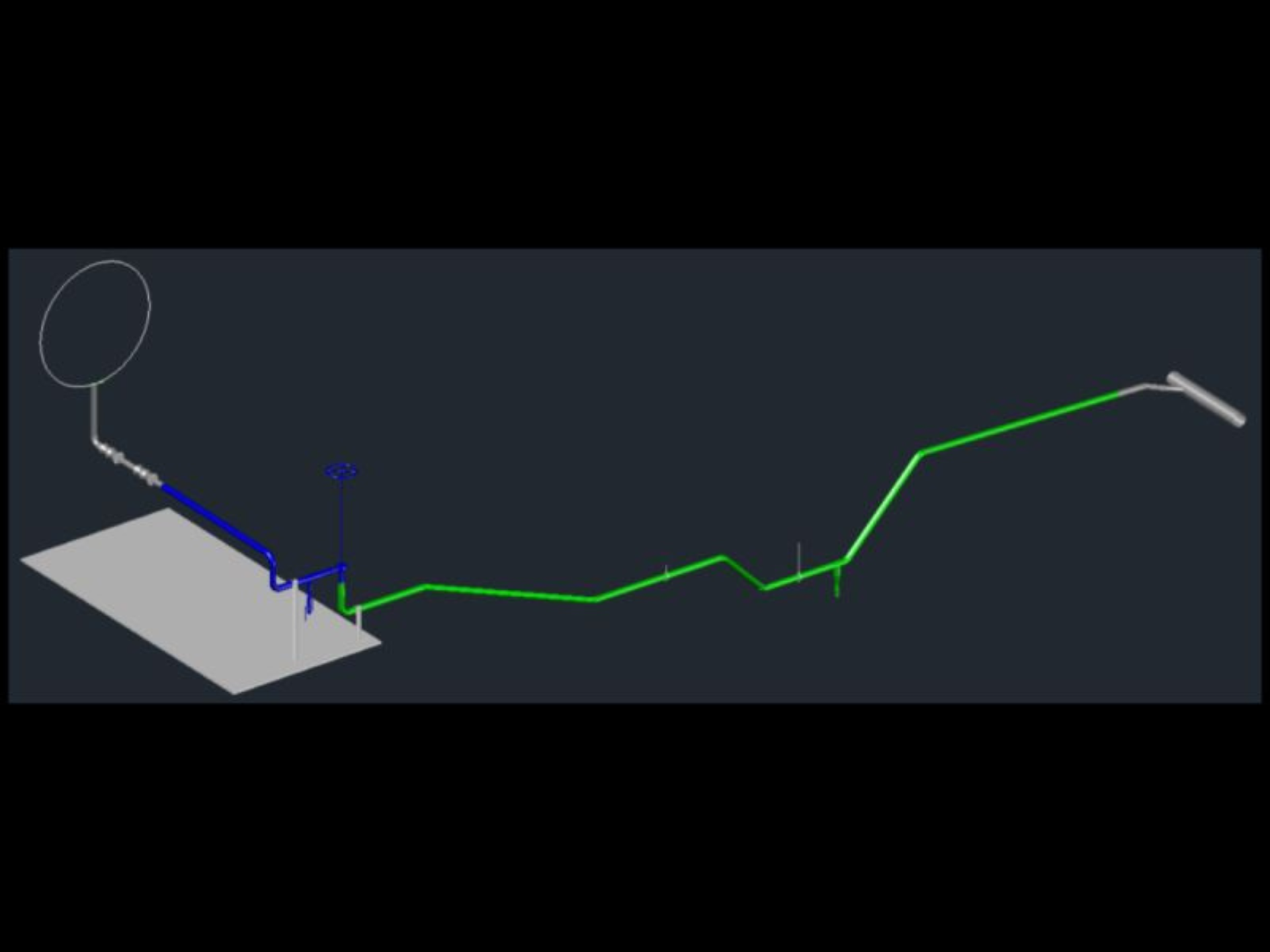

REDD was sought out by Equilon (joint venture between Shell and Texaco) to engineer, procure, and construct a novel design of a 1,500 barrel per day, skid-mounted, vacuum tansmix distillation unit at a Shell Oil Products Facility. REDD proceeded to model, design, engineer, and construct the skid while keeping the client’s specifications in mind. The package that was developed included the basis of design, all of the relevant process & flow calculations, PFD’s, P&ID’s, stream summaries, electrical diagrams, General Arrangement and elevation drawings, equipment purchasing, expediting schedule, and the skid-mounted trasmix module.

Though REDD is usually involved with installation and construction management, for this project Shell elected to install the unit while REDD provided technical assistance during installation and Start-Up. This included training by a qualified REDD person for three days at Shell’s facility to review operation and maintenance manuals. After facility start-up, REDD completed a performance acceptance test, ensuring that the system worked according to design.

REDD’s design allowed Equilon to operate the facility longer in-between cleanouts, averaging 26 weeks versus the industry average of 6 weeks.

Due to REDD’s small-scale approach to projects, and our emphasis on teaming with the client to achieve their business goals, REDD has consistently been the company of choice for those seeking to demonstrate the effectiveness of their novel technology or business approach. We take pride in our expertise in the transfer of technology, both to newly developing countries and to established commercial enterprises seeking the latest advancements in engineering and science.