Manufacturing Facility Automation & Expansion Design

We recently supported a manufacturing expansion project for a facility producing shampoo and conditioner. To help the client double production capacity – without increasing labor – our team provided detailed engineering and design services to integrate new automated equipment into their existing operations.

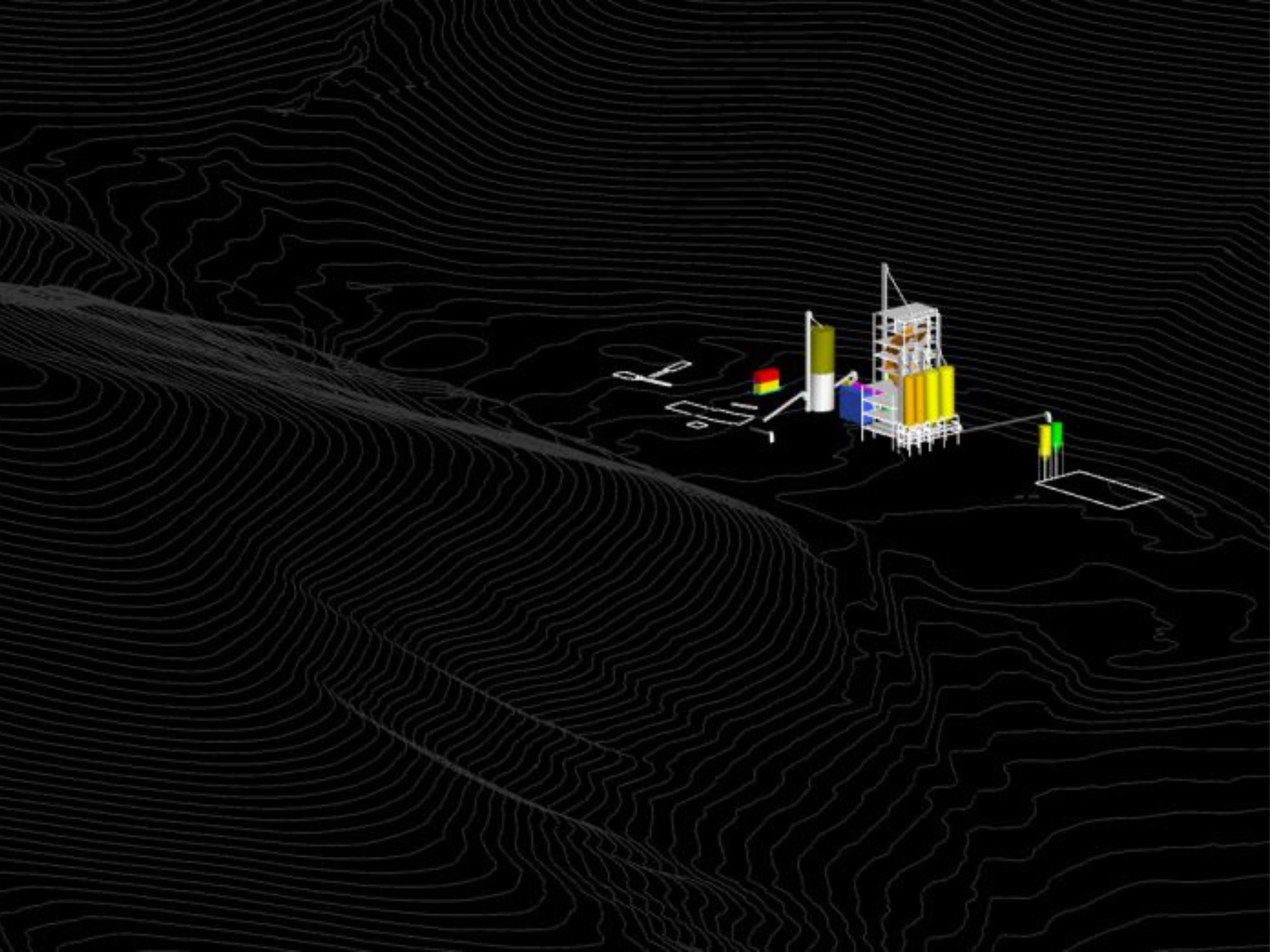

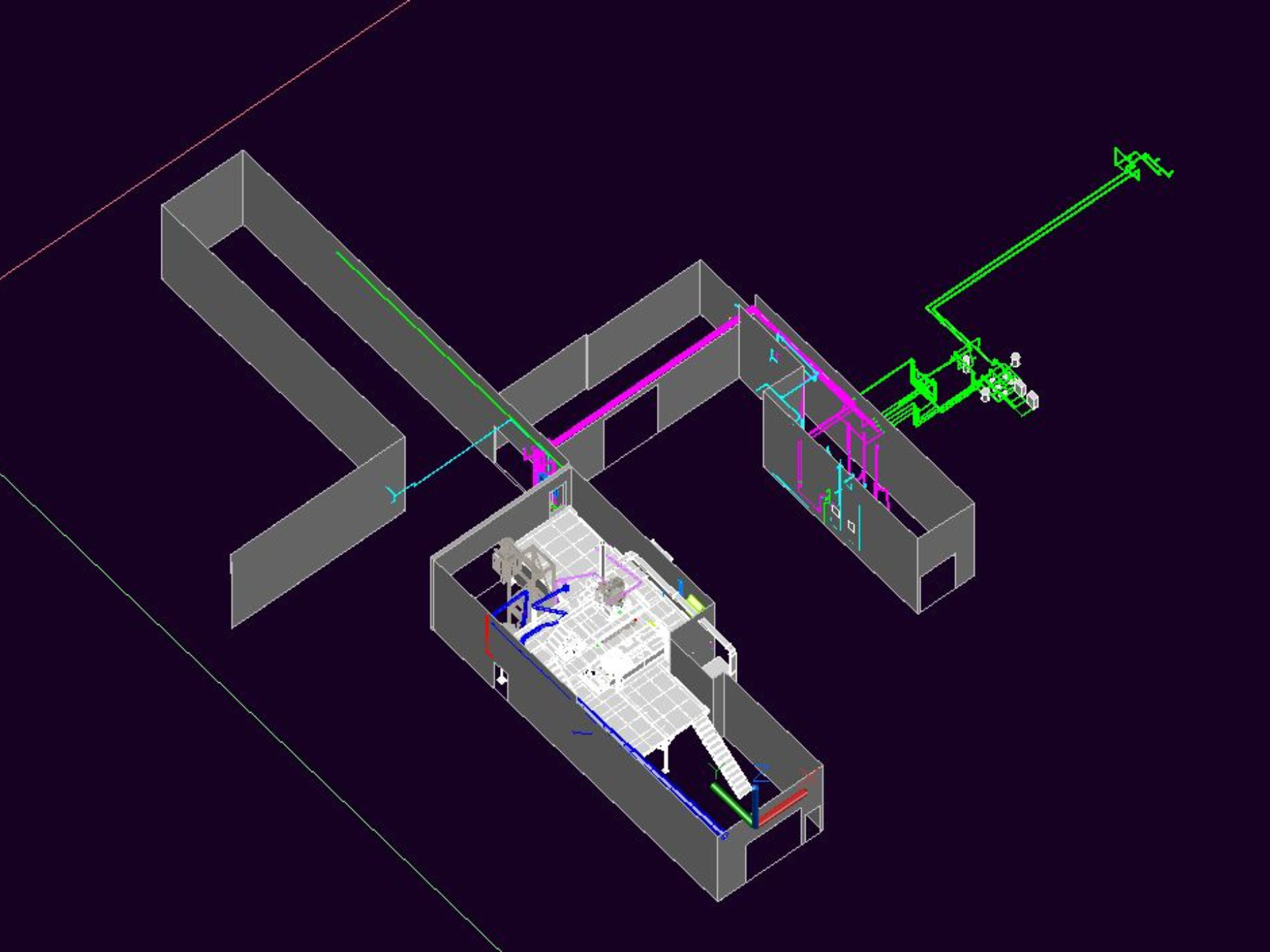

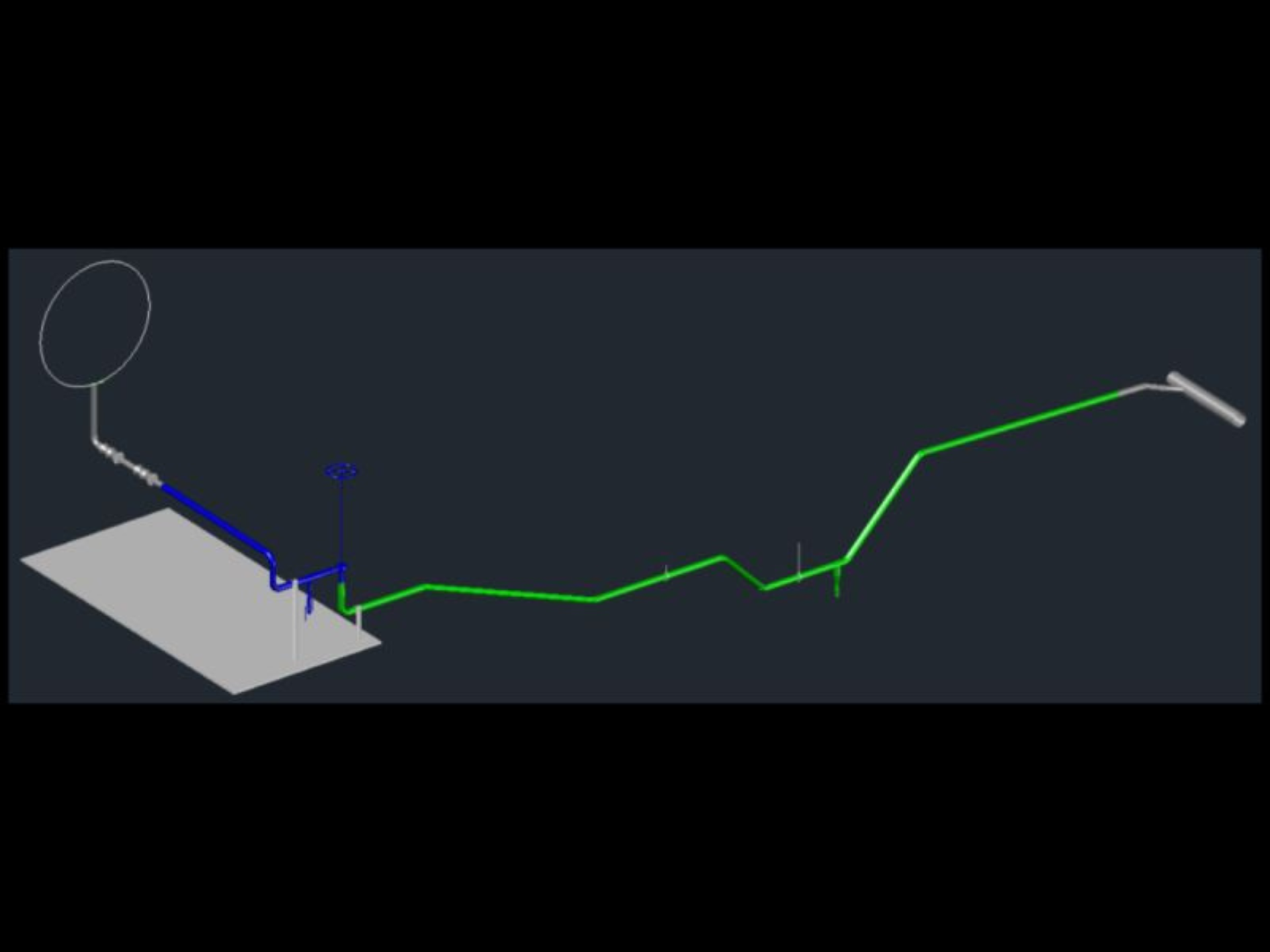

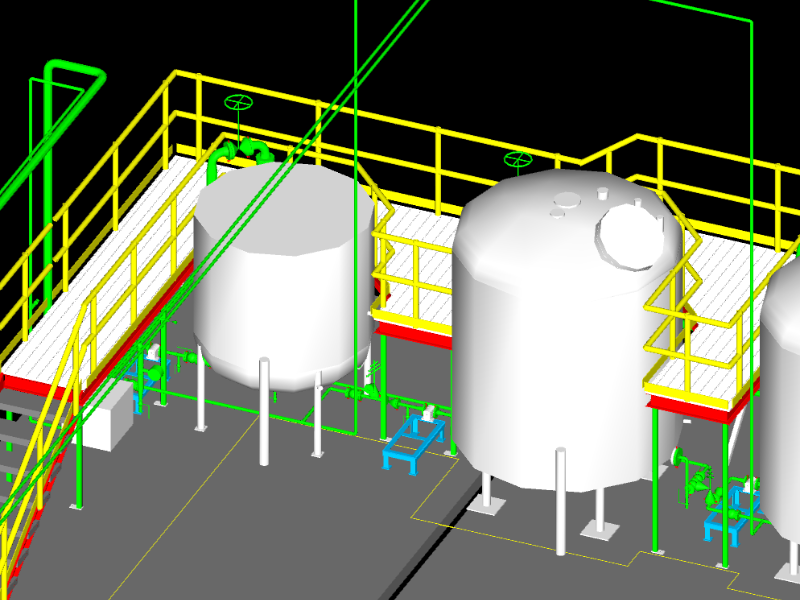

Our scope included 3D scanning and modeling to ensure accurate equipment placement, equipment specification, process design updates, and utility investigations. We developed detailed engineering deliverables such as P&IDs, piping plans, foundation layouts, and electrical system upgrades to support the installation of two automated production lines, steam jacketed kettles, metering pumps, an access platform, and a new boiler system.

The final deliverables included an Issued for Construction (IFC) package with comprehensive mechanical, structural, process, architectural, and electrical design documents, as well as procurement support for critical components. This expansion will streamline operations, enhance efficiency, and enable the facility to meet growing market demand.