P&IDS and PSM for Nitric Acid Systems

Adherence to Standards Pays off

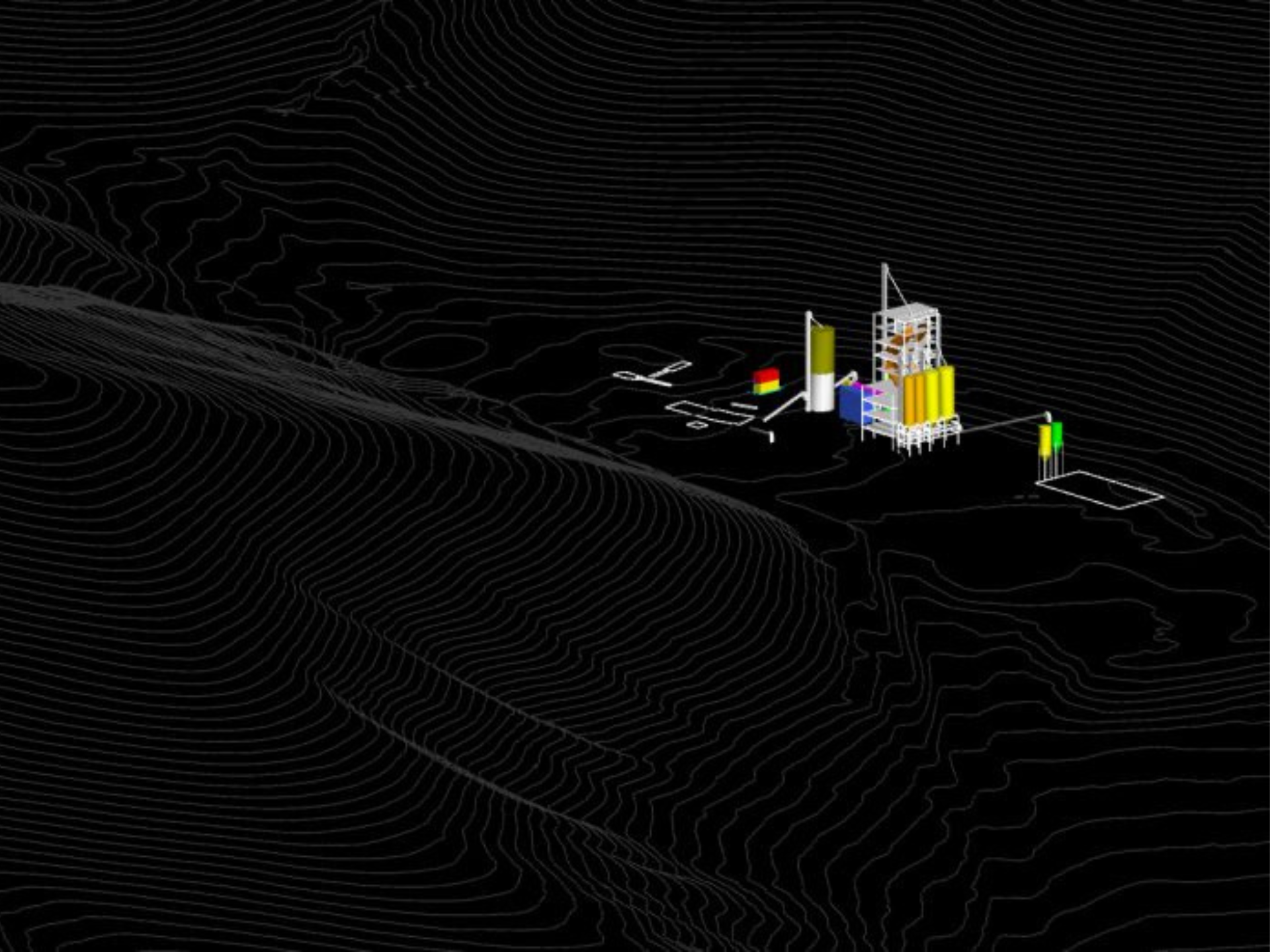

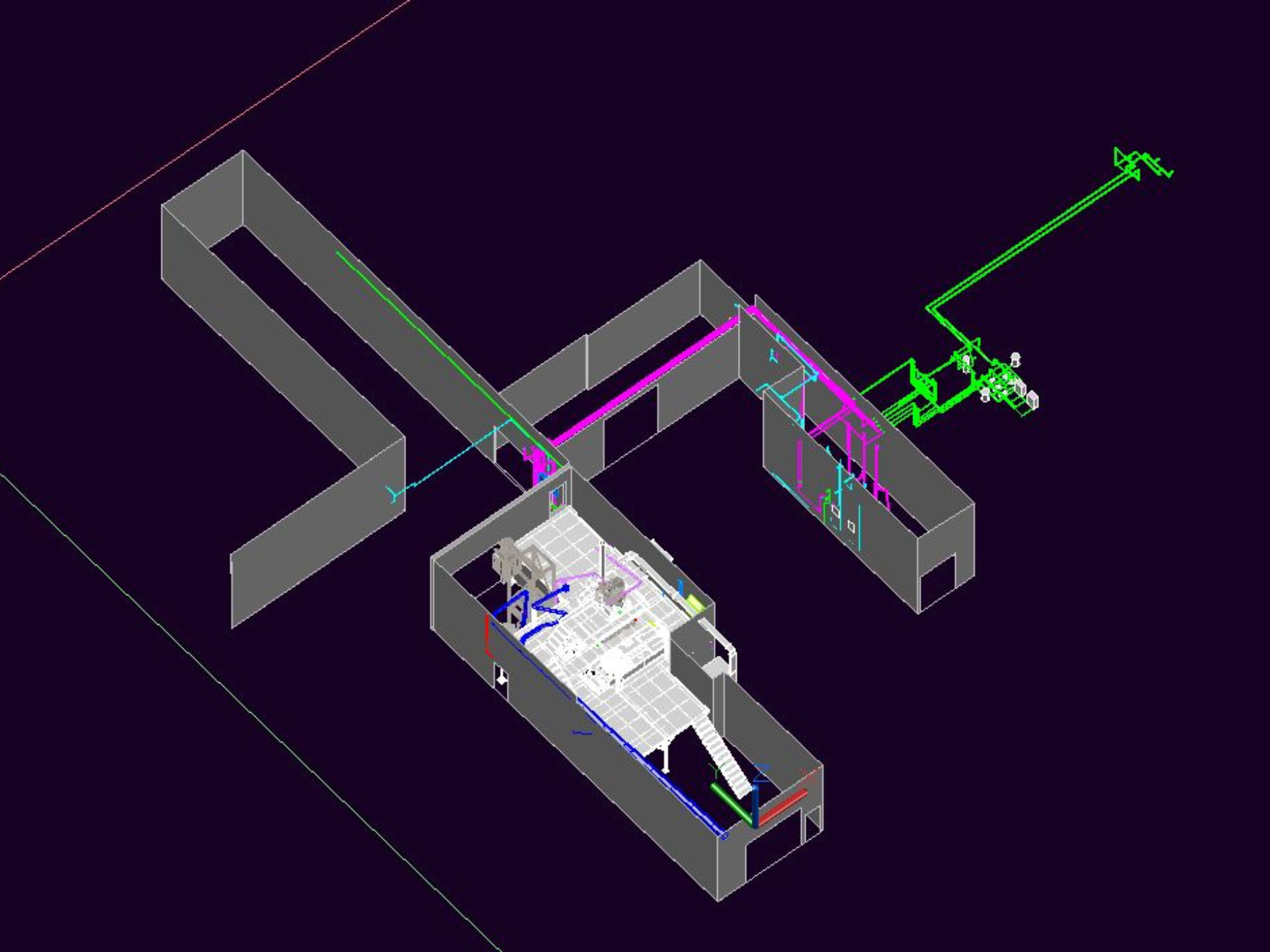

The client had a facility that was lacking P&ID’s and a PSM program for most of their process. They decided to develop a small portion of P&ID’s for a couple of buildings in their facility, and reached out to REDD to help provide P&ID’s for the remaining buildings and tie them together. The client also had REDD create a skeleton PSM plan for the buildings we were responsible for.

REDD’s staff included designers and drafters that specialize not only in P&ID’s & PFD’s, but also have practical experience in helping companies understand the requirements of process safety in general and Process Safety Management (PSM). Due to numerous jobs similar in nature to this one, REDD seamlessly assisted the client in generating P&ID’s for the buildings that had none at the time and tie them into existing P&ID’s of other buildings in the facility. REDD then proceed to lay out an initial bare-bone PSM plan for the client to build off of. REDD has years of general PSM experience and have developed comprehensive PSM standards which are strictly followed and always aim to exceed in both client expectations and industry standards.

Although drafting & design are seen by some as a low level commodity, at REDD we pride ourselves on beautiful drawings that clearly show the most important details of each type of drawing in a defect free manner. Due to the level of P&ID detail intertwined with our strict adherence to PSM Standards, when UOSH came in and reviewed the work that was performed, REDD’s work passed with flying colors. Unfortunately, the same could not have been said for the buildings that REDD was not involved with.