Process Safety Management Development

Safety First

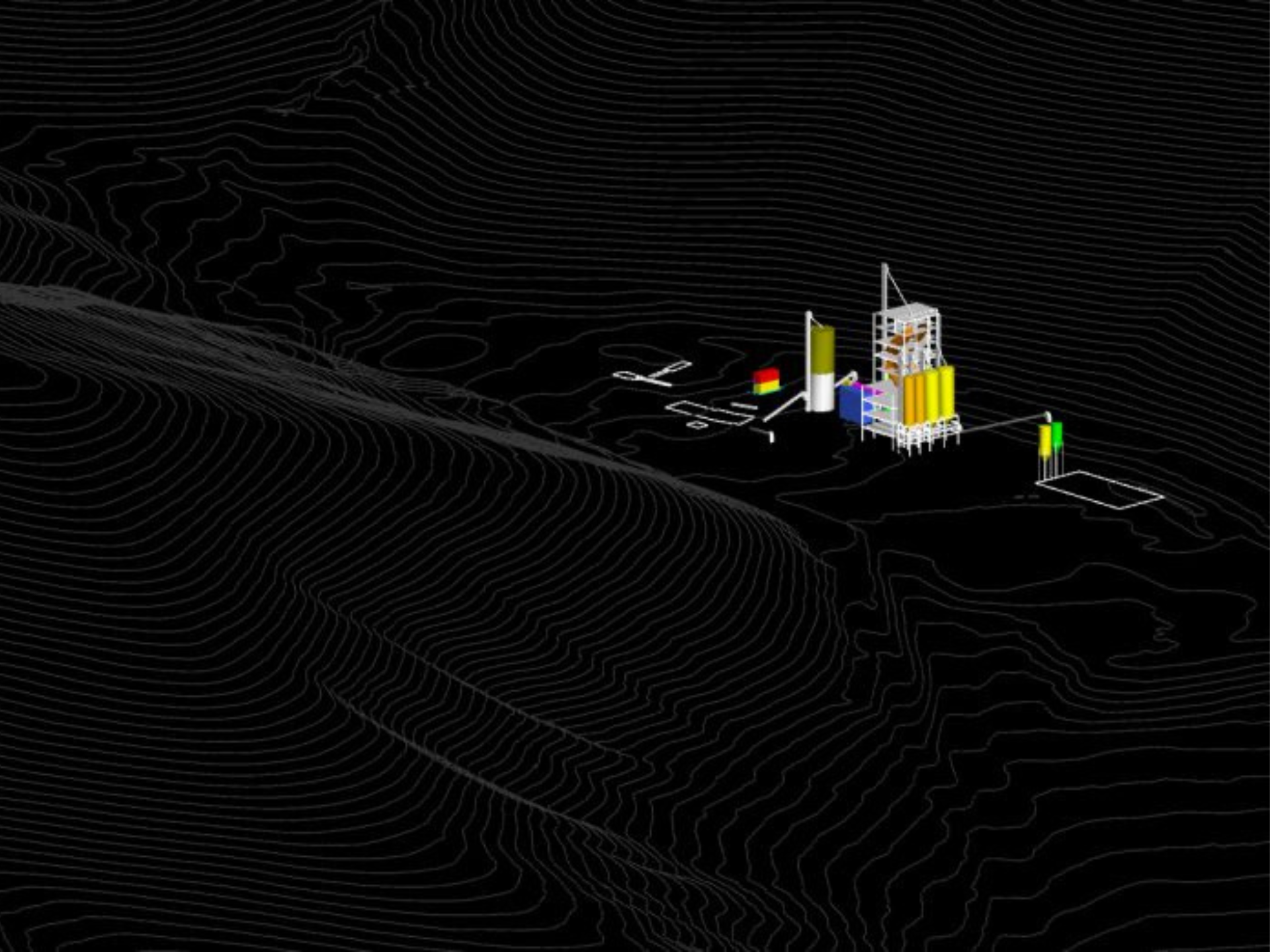

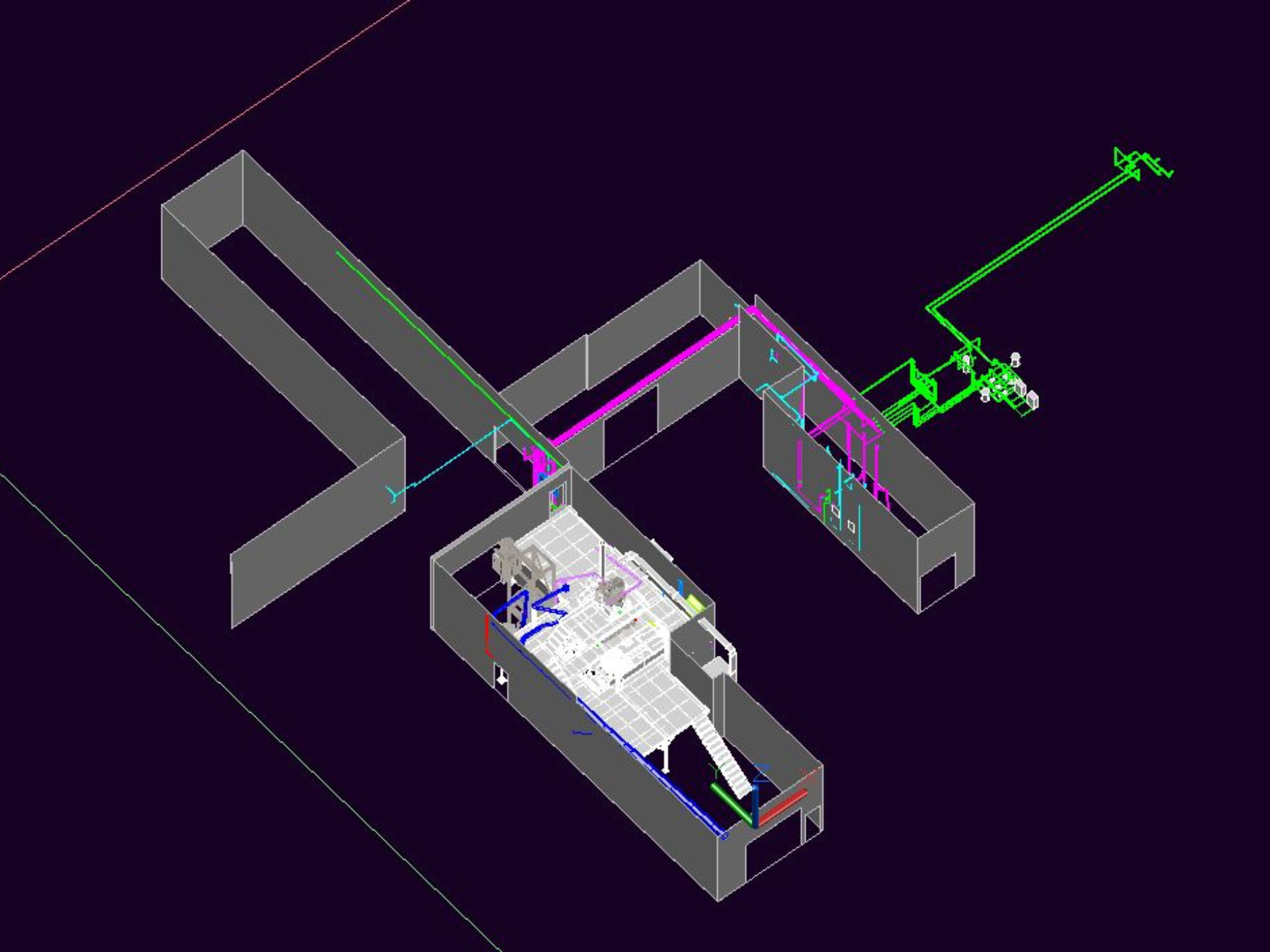

A geothermal powerplant called on REDD to help implement a robust PSM program for their production facility. In order to create a long-lasting Process Safety Management program, REDD started by working with the client to create a PSM Document Checklist. The documents generated by REDD for this checklist included Engineering Standards Documentation, Employee Participation, Process Hazard Analysis (PHA), Employee Training, Management of Change (MOC), Emergency Response Data, and Compliance Audit forms. REDD proceeded to collect and review P&ID’s and PFD’s to accurately input Process Safety Information (PSI) into their new REDD PSM Software. REDD then provided training on the PSM Program and the PSM Software.

To help close the gaps identified during the PSM program implementation, REDD facilitated a PHA. The REDD team prepared for the PHA and provided two engineers (a facilitator and a scribe) to lead the client’s management and operators through a HAZOP. REDD then delivered a report summarizing the PHA and included the HAZOP worksheet with a set of action items that needed to be performed after the PHA to properly meet safety & insurance guidelines.

The PHA was proven to be effective and as a result of this success, the program is still in use today as it helped to save money via increased efficiency, helped to make operational improvements, and contributed to an overall change in safety culture.