24-Hour Turnaround Operations Made Easier: Relieving the Pressure with Smart Solutions

REDD provided turnaround support for a refinery and designed replacement systems for out-of-compliance PSVs.

PSV Turnaround Support

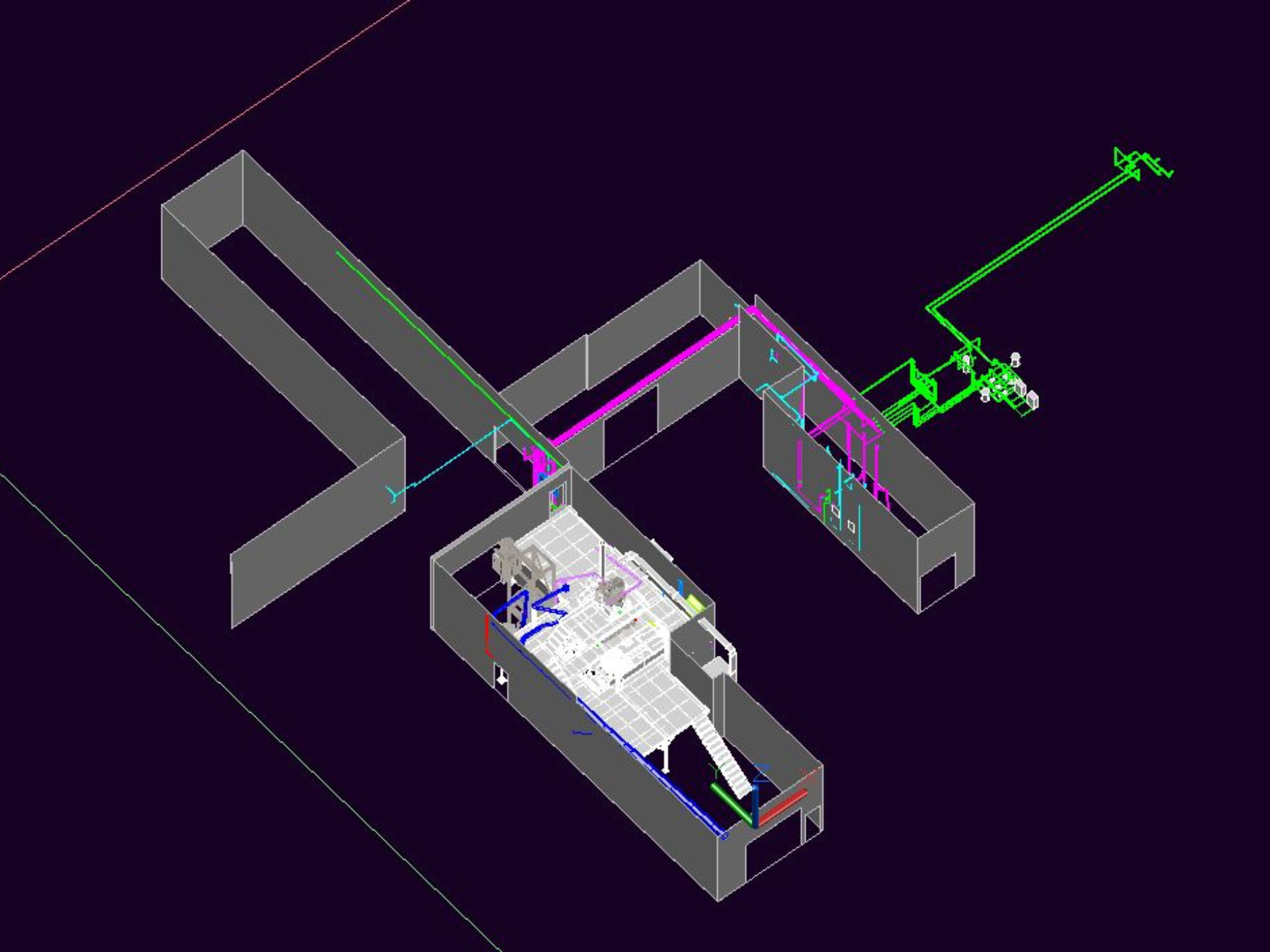

A local refinery had planned a large turnaround procedure across several units. With all internal managers occupied with other turnaround work, they needed construction management support for overseeing the modification and replacement of 14 out-of-compliance PSV lines.

Since REDD had designed the PSV modifications and had many years of construction management experience, the refinery contracted REDD to supervise the PSV turnaround installation. REDD provided 24-hour turnaround support for the project, managed contractors, and reported to the client on construction progress.

Upgrades to the system included reinstalling isolation valves at the proper orientation, adding bypass lines, adding vents and drains, building platforms to allow operator access to previously unreachable PSVs, and upsizing PSVs where necessary, including the replacement of over 100 ft of piping extending from the flare header to the top of a distillation column.

Thanks to REDD’s ability to provide both design and construction management services, the refinery was able to bring many 30–60-year-old PSV lines into compliance with the latest safety standards and complete the turnaround work on schedule. And, over 3 weeks of 24-hour operations, REDD’s supervised contractors had an impeccable safety record with no lost-time injuries.