Salt Plant Expansion Study

Sturdy Plant Expansion Study Strengthens Salt Suppliers Strategy

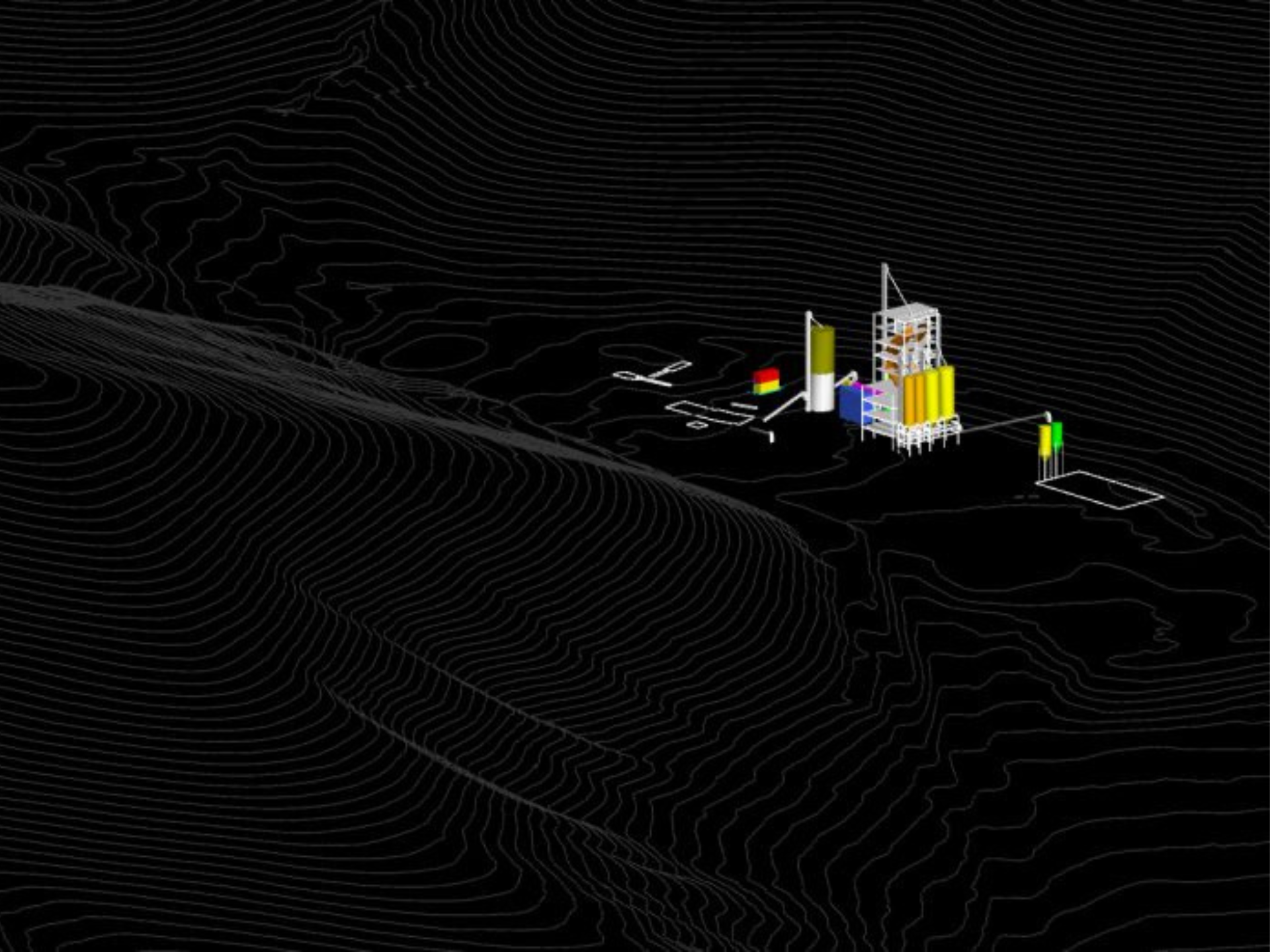

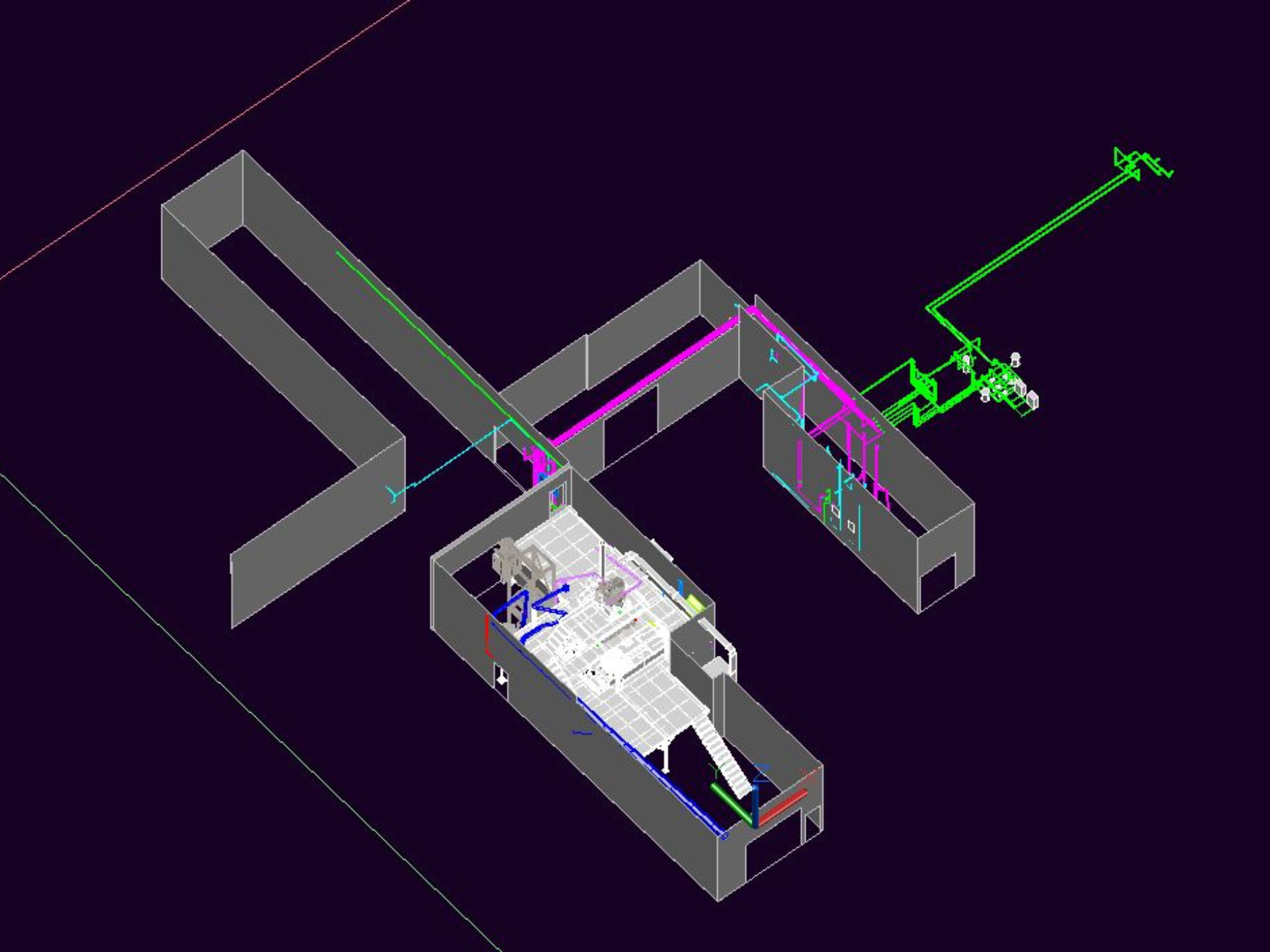

A local salt plant, seeking to increase production and boost efficiency, contracted REDD to identify process bottlenecks and estimate the cost of the necessary upgrades. REDD conducted a comprehensive study of the plant and process, detecting significant bottlenecks and opportunities to increase efficiency in the following:

- The plant lacked sufficient utilities to meet peak demand in summertime. Recommended adding greater electrical and steam capacity and replacing aging transformers.

- The material crushing system had structural deficiencies and contributed to poor air quality and adverse working conditions. Recommended installing all-new crushing system with three train unloading stations to increase capacity and improve safety with better air quality and working conditions.

- Harvest reactor tanks could not adequately measure and control thickener addition to the slurry mix, resulting in excessive water addition and loss of product. Recommended installing new tanks that would reduce reaction time and thickener usage, eliminating a significant process bottleneck and increasing mineral harvest efficiency.

- Rotary kiln driers were aging, requiring frequent maintenance and disrupting production. Recommended installing new, more-efficient dryers that would require less maintenance.

- Plant cooling system would need to be uprated to handle increased production. Recommended doubling the cooling capacity to accommodate future needs.

Thanks to REDD’s experience in process evaluation and cost estimation, the client received a detailed roadmap to achieve their goals and gained a realistic understanding of the capital investment required to do so, preventing the headache of busted budgets and the frustration of underperforming upgrades.